Our excellent technical skills of manufacturing and molding have been highly rated by our clients.

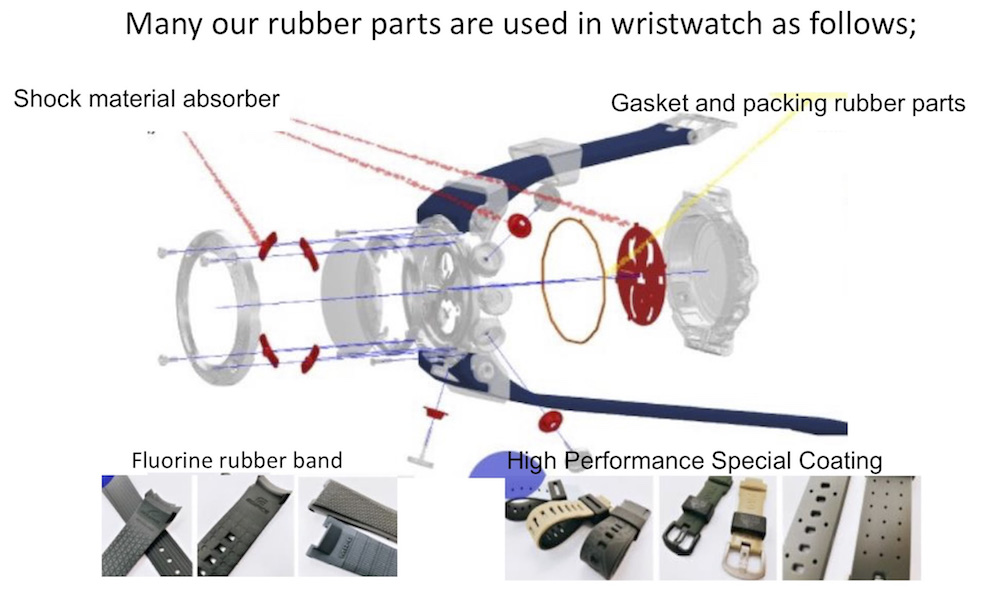

Our rubber parts are used in wristwatch as shock material absorber

Our gasket and packing rubber parts are used in a wristwatch as airtight products.

No1-1 Fluorine rubber band are excellent in flexibility and durability

No1 High Performance Special Coating

Silicone rubber, which has poor wear resistance and is prone to dust, may be coated on the surface. However, most of the coatings used on silicone rubber were either not durable and did not last long, or they had poor designability, making them unsatisfactory for exterior parts that required high specifications. The special coating developed by our company in collaboration with a material manufacturer is a high-performance coating that has succeeded in “wearresistance”, “adhesion” and “followability “standards.

No2 Low Hardness EPDM

Our compounding technology has made possible to replace parts that are low hardness EPDM. These parts include sponge molded products with solid rubber resulting in cost reduction

Integrated molding of metal/resin and rubber

We incorporate in many composite moldings of different materials such as metal and rubber With a wealth of experience in integrated molding, such as vulcanization adhesion and mold design know-how, not only can we contribute to cost savings , such as reduction of the number of parts and assembly man-hours, and t also expand the variety of mechanism design and create new products to add value for our customers.

Tape sticking line

Toatec’s tape application line, which uses a surface modification device and a semi-automatic sticker application machine, improves the adhesiveness of the tape application surface, broadens the range of material selection, and product cost savings.

・Surface modification device

・Semi-automatic sticking machine